Delivering Under Lockdown: Keeping the UK and our Employees Safe

The impact of the Coronavirus on business and manufacturing has been staggering, bringing offices and factories across the UK to a standstill. However, when it comes to delivering the Nation’s Defence there can be no stopping, with some manufacturing required to deliver solutions that the Ministry of Defence deem urgent capability requirements (UCRs) and services which are critical to maintaining military capabilities on Land, Sea and in the Air.

Throughout this challenging time Thales has kept the factories going where necessary even if it means adopting some rather novel approaches in order to get the job done.

“The response from our whole team has been outstanding,” says Bernie O’Neil, Head of Operations at Thales’ Glasgow site. “The way the remote Project Engineering teams have responded to this new way of working has been brilliant. Our ability to maintain our deliveries and our customer commitments is testament to the outstanding people we have in our team”.

The COVID-19 situation has meant big changes to work patterns and the factory itself. “In order to continue to deliver to our customers we have changed how we achieve that,” continues Bernie, “by introducing shift working for production, with all other staff working from home, significantly reducing numbers on site. The whole site has had to be reconfigured to support safe working during this time”.

This is just one of a whole host of changes that have had to rapidly be brought into force to meet the ‘new normal’ for working practices, not least the need to keep Thales employees safe.

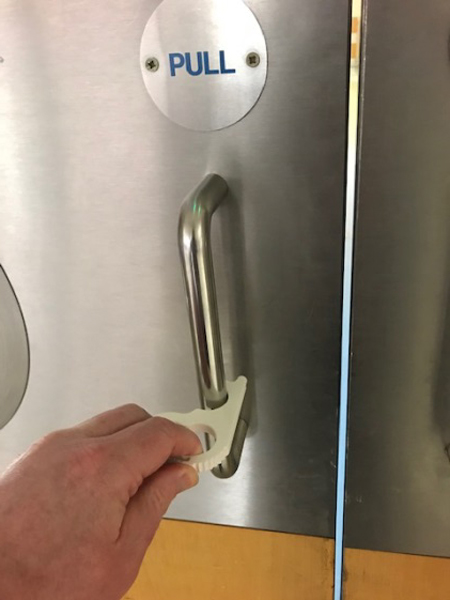

Bernie easily rattles off the list of actions taken; “We’ve introduced a full suite of C-19 protective measures. We have two meter distancing in place across all activities, including break-out areas, clean rooms, people traffic and desk areas. Drop-off points have been introduced at key places to negate unnecessary handovers. We’ve even designed, 3D printed, and distributed door opening devices, as well as issued personal hand sanitizers and individual styluses for keypads”.

Bernie and her team of Industrial Architects and shift managers have also removed or restricted the number of common touch points (turnstiles, keypads, PPE doors), introduced a one way system throughout the facility, and closed off entirely areas of the facility to help focus cleaning efforts where they are most needed.

The list of actions taken is seemingly endless.

However behind this activity lies a very good reason why Thales is continuing to work during this time: to support the UK MoD. Giving evidence to MPs on the House of Commons Defence Select Committee, the UK’s Defence Secretary, Ben Wallace, made clear that there was evidence that the UK’s enemies were trying to exploit Covid-19, “in order to damage us”, emphasising that the work of national security continues regardless.

Whether delivering crucial services to the Royal Navy and their submarines, including spare parts and repairs, or providing new and critical capabilities that have arisen as a counter to an ongoing threat, Bernie and her team are finding a way to deliver.

Beyond the factory some Thales staff, armed with ‘Key Worker’ letters from the Dept of Trade (issued via the company’s online HR portal), have even been working in support of the MoD ‘in the field’. The last few weeks have seen critical trials of a new system for the Royal Navy which will have a direct positive impact on the deployment of the UK’s new Aircraft Carrier, HMS Queen Elizabeth II, on her maiden voyage next year. To meet the timeline of her deployment the trials had to go ahead, but under some rather unique and at times challenging circumstances.

The outdoor trials in the west of Wales saw significant social distancing measures, separate offices and a one-way system put in place on the range. Any manual handling or physical operations that required more than one engineer had to be coordinated around strict two meter separation guidelines and whilst wearing PPE. Most unusual, for trials at least, was that travel was strictly by ferry rather than air routes, separate vehicles were hired for each team member, and self-catering cottages were hired, instead of hotels, with local farm produce made available to minimise travel and provide necessary team separation.

When asked what the biggest challenge has been during this current situation, Bernie O’Neil said that it was making so many changes in such a short space of time whilst still delivering for the customer.

“The innovation we apply to delivering solutions to our customers has been applied to great effect to this challenge”, she noted, adding; “the commitment and dedication the production team have displayed throughout this time has been truly amazing.”

As the Covid-19 pandemic continues to spread, Thales employees are fully mobilised in the battle to overcome the virus and deal with its consequences. Find out what Thales is doing as a company and how individual employees are showing their solidarity by lending technical expertise and innovative ideas here.