Lithgow Arms celebrates 110 years!

On Wednesday 8 June, 2022, our Lithgow Arms site celebrated its 110-year anniversary. We look back on the story of Lithgow Arms, delight in some little-known facts and chat to General Manager Bruce Hutton and Business Improvement Manager David Forbes about their favourite memories over the decades and what makes Lithgow Arms such a special workplace.

How it all began

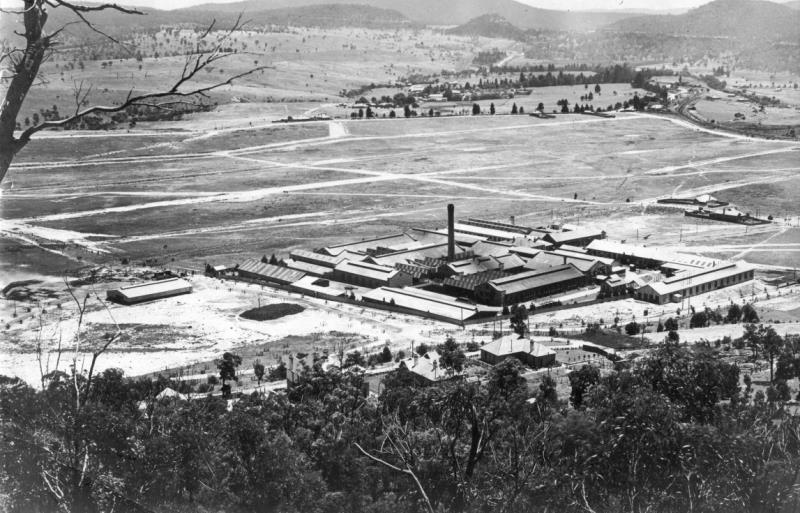

In 1907, Australian Prime Minister Deakin officially announced Australia's defence supply would become a sovereign capability and no longer rely on Britain. Just a few months later, in early 1908, a section of land was purchased in a small coal mining town 140km west of Sydney. This site would go on to become the Lithgow Small Arms Factory, opening on 8 June 1912.

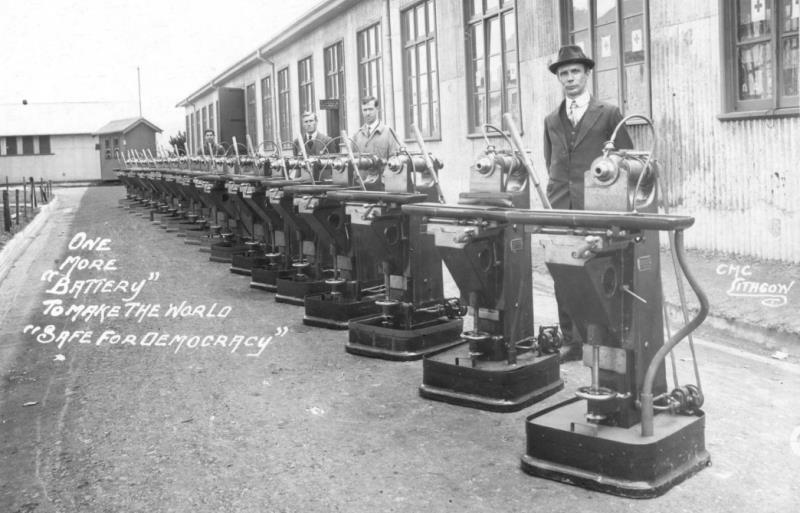

Two short years later, World War I began and Australian forces were sent abroad carrying Australian-made, superiorly built rifles made at Lithgow Arms. During WWI, which ended in November 1918, the factory manufactured 133,600 rifles and employed over 1,300 people. This was a significant jump from the 15,000 manufactured and 120 persons hired in the factory’s initial year of operation.

Commercial era begins

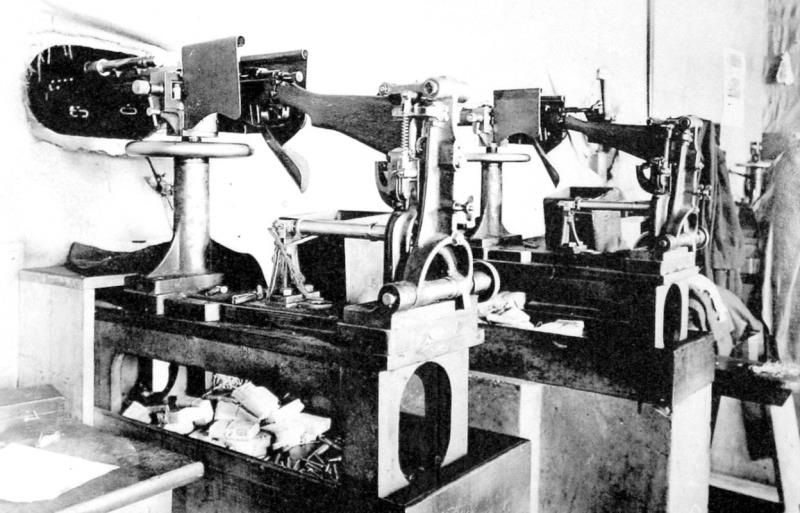

In the years after WWI, the factory branched out into commercial work. Before long, Lithgow Arms employees were producing everything from aircraft parts to shearing handsets, cinema projector parts and state-of-the-art handcuffs. At one stage, the site was even making artificial limbs!

In 1941, World War II erupted and the factory saw a sharp increase in activity again. Between 1939 and 1945, Lithgow Arms manufactured 439,000 rifles and employed over 12,000 people across various sites, with 40 per cent being women. To produce this number of small arms for the Australian Defence Force, who were by now being deployed all over the world, several feeder factories were established in nearby areas - including Parkes, Orange, Dubbo and Mudgee – to support the workload.

Lithgow Arms has proudly supported Australian soldiers on battlefields around the world, including Gallipoli, North Africa, Borneo and Kokoda, East Timor, Iraq and Afghanistan just to name a few.

Business Improvement Manager David Forbes started at the factory 40 years ago and recalls his first day:

I began as an apprentice Tool Maker and remember walking through the gates on my first day and being completely blown away by the scale of it all. It was like a mini city here on site. There were doctors and nurses, a team of painters who kept the place looking brand new, and there were people everywhere. This facility really has been an integral part of Lithgow’s history. Even today we have multi-generations of families working here."

Forming its present-day identity

General Manager Bruce Hutton started at the factory in 1990 and one of his favourite memories is the pomp and ceremony when the first semi-trailer load of F88 production weapons was sent on its way by the then Minister of Defence, Robert Ray, that same year.

Over the years Bruce has seen the site transition from the “Office of Defence Production”, to the government owned corporation Australian Defence Industries, a Joint Venture between Transfield and Thompson CSF, to present-day 100% ownership by Thales. Under Thales ownership, Bruce has observed the introduction and investment in new technologies and automation, facilities infrastructure upgrades, changing from a build-to-print organisation (making other companies products) to a full Research & Development facility manufacturing our own designs, and shifting from traditional manufacturing "Batch and Queue" processes to LEAN pull systems to reduce waste in the production process. He's also seen the product range diversify, particularly in the civil market, and changes in attitude towards the importance of having a domestic Small Arms capability.

However, Bruce believes some of the most significant changes have been the cultural ones, such as the breaking down of cultural barriers between white collar and blue collar workers, improved communications and organisational transparency and increased flexibility and multi-skilling of the workforce. Although the size of the operating site has reduced by 50% and there's now approximately 140 staff compared to 700 when Bruce first started, the sense of purpose and team spirit remains alive and well.

I have to say, I have thoroughly enjoyed my 32 years with the company so far, I still spring out of bed each day and head to work looking forward to making a difference.

I love working with the team at Lithgow, they are just like family. I love their can-do attitude, sense of humour and the camaraderie. There is never a dull day when working in paradise!"

Modern day Lithgow

Our Lithgow team continues the legacy of delivering world-leading small arms manufacturing to the Australian Defence Force (ADF), and supporting Australia’s sovereign capability.

Commercially, Lithgow Arms also exports firearms to 14 countries around the world and in October 2020 the business achieved 22,000 civilian rifles sold.

More than 200 suppliers are located in New South Wales and over 92% of content used in production is sourced locally or made on site.

Not even the COVID pandemic could dampen the team’s dedication to continue delivering to their customers. Lithgow Arms kept operations running and approximately 18 per cent of staff worked from home, with only those essential to the conduct of safe operations remaining on site. Behind the scenes, local management worked hard on supply chain analysis whilst precautionary measures, such as staggered shift start times and meal breaks, were implemented on the frontline.

The business continues to go from strength to strength, with a new manufacturing partnership between Lithgow Arms and Rheinmetall Defence Australia announced in September 2021 to manufacture key components for the Rheinmetall MK-30-2 cannon capability in support of the ADF’s Land 400 program.

In February 2022, the first phase of a $6.5 million industrial plan to transform the Lithgow Arms facility began. The investment will establish a modern manufacturing and integration hub for the design, development and precision manufacture of next generation weapons systems for the Australian Defence Force, industrial partners and export customers.

Other interesting facts

Our Lithgow Arms site is memorable for other reasons:

- The army isn’t their only customer – the team have also made rifles for Hollywood movies such as Alien Covenant and Pacific Rim!

- Prince Lavaka of Tonga (who later became the country's King) made a royal entrance during his visit to Lithgow Arms when he flew on to the site via helicopter!

- Two passionate Lithgow employees undertook basic 5-week Army Reserve training at Kapooka to gain a true appreciation of the rifle used by our customer.

- In the past two decades Thales Lithgow, in partnership with training organisation Skillset, have produced over 60 of the region's most talented tradespersons.

- Thales Australia’s first ever Reconciliation Action Plan artwork called ‘Creating Together’ was created by Leading Hand Machine Setter at Lithgow, Rick Slaven.

As the world continues to change we look forward to seeing Lithgow Arms continue to adapt and thrive over the next 10 years:

The future of Lithgow Arms will see more electronics and software built into our products as standard offerings and an increasingly diverse customer base. I believe the factory will continue to evolve and re-invent itself to ensure it always remains relevant to the needs of its customers, as it has done for the last 110 years."

Bruce Hutton, General Manager Lithgow Arms.

110 years of operations has taught us that circumstances change, and it is not the largest business that survives but the business that is most responsive to change. The Lithgow team are very resilient and proud of it."

David Forbes, Business Improvement Manager at Lithgow Arms.

From all of us, happy 110 years Lithgow Arms and cheers to many more!